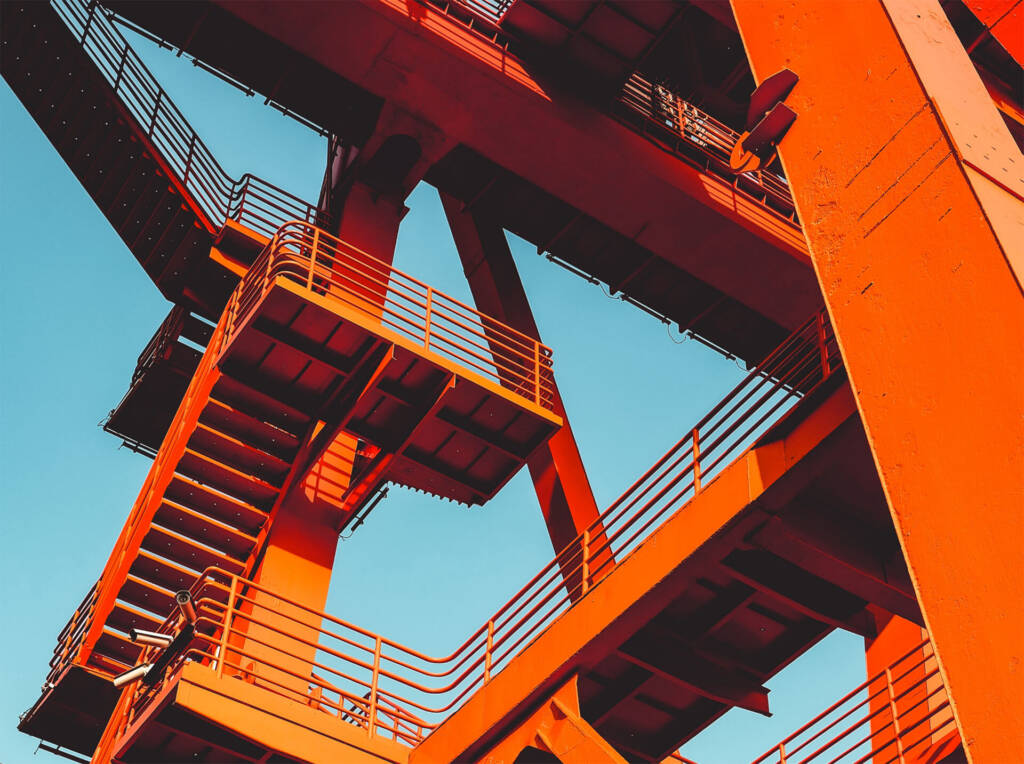

Our Pumping Unit

At Mugam Oil Refinery, our pumping unit is a critical component of our operations, designed to facilitate the efficient transfer of crude oil and refined petroleum products throughout the refinery and to various distribution points. With a focus on reliability, safety, and precision, our pumping unit plays a vital role in ensuring seamless operations across all stages of our refining process.

Advanced Pumping Technology

Our pumping unit is equipped with state-of-the-art technology, designed to handle various fluids under different pressure conditions. We utilize a range of pumping solutions, including:

- Centrifugal Pumps: These pumps are ideal for transferring liquids at high flow rates, making them suitable for moving crude oil and refined products throughout the refinery.

- Positive Displacement Pumps: Used for applications requiring precise flow rates, these pumps are essential for transferring viscous fluids and ensuring accurate dosing in our processes.

- Submersible Pumps: For applications that require pumping from deep wells or tanks, our submersible pumps are engineered for efficiency and reliability, ensuring optimal performance in challenging environments

Safety and Reliability

Safety is paramount in our pumping operations. We implement comprehensive safety protocols to protect our personnel, equipment, and the environment. Key safety measures include:

- Regular Maintenance: Our pumping unit undergoes routine inspections and maintenance to ensure optimal performance and compliance with safety standards. Preventive maintenance helps identify potential issues before they escalate.

- Emergency Shut-off Systems: We have integrated emergency shut-off systems that can be activated quickly in the event of a malfunction, preventing spills and minimizing risks.

- Training Programs: Our personnel are trained in the operation and maintenance of pumping equipment, as well as safety procedures to ensure a safe working environment.

Environmental Considerations

Mugam Oil Refinery is committed to minimizing our environmental impact through sustainable pumping practices. Our initiatives include:

- Leak Detection Systems: We utilize advanced leak detection systems to monitor pumping operations continuously. These systems help us identify and address potential leaks promptly, protecting the environment.

- Energy Efficiency: Our pumping unit is designed for energy efficiency, reducing power consumption while maintaining high performance. By optimizing our operations, we aim to minimize our carbon footprint.

- Spill Containment Measures: We have implemented spill containment measures around our pumping unit to prevent any accidental release of liquids into the environment. This proactive approach is essential for protecting surrounding ecosystems.

Streamlined Operations

The efficiency of our pumping unit is crucial to the overall success of Mugam Oil Refinery's operations. We employ advanced automation and control systems to ensure smooth, coordinated operations:

- Real-Time Monitoring: Our pumping systems are equipped with real-time monitoring capabilities, allowing us to track flow rates, pressure, and other critical parameters continuously. This data is used to optimize performance and ensure safety.

- Integration with Other Systems: Our pumping unit is seamlessly integrated with other refining processes, allowing for smooth transitions between different stages of oil processing. This integration ensures that our operations remain efficient and responsive to market demands.

Conclusion

The pumping unit at Mugam Oil Refinery is essential to our commitment to operational excellence and safety. By leveraging advanced technology, prioritizing safety, and implementing environmentally responsible practices, we ensure that our pumping operations meet the highest standards. Our dedication to efficiency and reliability enables us to deliver high-quality petroleum products to our customers while minimizing our impact on the environment. Through continuous improvement and innovation, Mugam Oil Refinery remains at the forefront of the oil refining industry, ready to meet the energy needs of today and tomorrow.